Making coffee cups. Equipment for the production of paper cups (made in China)

Production paper cups is a promising type of activity that does not require large initial investments, as well as special knowledge and experience. After all, disposable tableware has always been in demand, not only in large cities, but also in small ones populated areas. It is worth noting that plastic products are gradually giving way to paper products. This is due to the fact that the raw materials for its production are not so harmless. Paper is an environmentally friendly product that can completely decompose within three years.

Are paper cups produced in Russia?

What are the features of paper cup production? The business of manufacturing such utensils will begin to pay off almost immediately. After all, paper products are practically not produced in Russia. At the moment, there are no more than 20 companies that produce such dishes. They are located in the Urals, as well as in the central part of the country. However, most of them are engaged in the production of coffee glasses.

While foreign companies offers a wider range. The main suppliers of paper cups are European organizations, as well as Vietnam, China and Korea.

Is this business relevant?

The production of paper cups is an unoccupied niche in the market of our country. After some time, such a business will begin to bring considerable income to its owner. This is due to the almost complete absence of competitors, a large number of consumers, as well as year-round demand. All you need to do is study the relationship between supply and demand, as well as purchase necessary equipment for the production of paper cups and raw materials.

Advantages

The business of manufacturing paper tableware, in this case cups, has many advantages, among which it is worth highlighting:

- Payback of the enterprise. All investments will be returned to the owner within 6-12 months.

- A small amount for starting capital. To purchase raw materials and equipment, you will need about 600 thousand rubles.

- The main production line is capable of operating throughout the day without stopping.

- A machine with sufficient power is capable of producing up to 50 units of products per minute.

- In the manufacture of such products they use modern technologies, which guarantees high quality products.

- The cups are made from In this case, the edges of each product are fixed by ultrasonic welding.

What is required to organize production

So, how to start a paper cup production? A business plan is a very important thing that is drawn up after registration of an enterprise. This takes into account information obtained after a thorough market study. A business plan allows you to determine supply and demand, occupy an empty niche and identify competitors. To start your own business you need:

Production Features

It is worth noting that the qualifications of employees are not particularly important, since modern equipment is used for the production of paper cups. Thanks to this, the process is completely automated. Production of such a plan is considered safe for environment and man.

As practice shows, the most hot commodity are coffee cups with a volume of 100 grams. Such containers are often used in the vending trade. Tea cups with a volume of 200 grams are also in demand. It is worth noting that such dishes can be used not only for hot, but also for cold drinks.

Equipment selection

The production of paper cups is impossible without special equipment. Its cost directly depends on the country of origin, as well as on the model of the unit itself. The main supplier of such machines is the USA, as well as Korea, China and some European countries. Each unit has its own characteristics.

When choosing equipment, it is recommended to carefully study all accompanying documents. Do not forget that the reputation of the company producing the machines also matters. This factor is also worth paying special attention to. This will help you decide on the choice of units. The average cost of a machine is about 600 thousand rubles.

Equipment from Europe and China

According to experts, the machine for the production of paper cups, manufactured in Europe, has high productivity and power. The unit is capable of producing up to 250 units per minute. In addition, such equipment is considered not only economical, but also expensive. The cost of the machine exceeds 1 million rubles.

As for equipment from China, it is not very expensive. However, the units have disadvantages. First of all, this is poor build quality. Because of this, equipment often breaks down and requires repair. In addition, the units have low power and are capable of producing 30-80 cups within a minute.

Types of machines

It is worth noting that there are different machines for the production of paper cups. The best ones are those that use ultrasonic soldering. They are able to function non-stop and for a sufficiently long time. high speeds.

There are units that produce paper cups by thermal soldering. This is the simplest, but at the same time reliable method of gluing workpieces.

What's worth buying

In addition to the machine, the entrepreneur will have to purchase replacement blanks. They are required for the manufacture of containers of various volumes, sizes and shapes. Otherwise, it will be possible to establish production certain type cups. If you want to make containers with ornaments, inscriptions or a logo, you will have to purchase a unit capable of applying a certain stamp to paper.

In some cases, a machine for grinding raw materials is required. Such equipment not only cuts paper, but also speeds up the process of manufacturing blanks from thick fabric.

Consumables

The paper for the production of paper cups must be sufficiently thick and laminated. A certain consumable material should also be sufficiently dense. This figure is 120-280 grams per 1 m2.

Finnish paper appeared on the raw material market relatively recently. This consumable quickly gained popularity. In addition, there are domestic enterprises that produce laminated paper for the production of cups.

When purchasing raw materials for your enterprise, you should take into account that to produce 400 thousand units of products you will need at least 5 tons of consumables.

Is such an enterprise profitable?

Production of paper cups is a good idea for those who want to start their own business and have small capital. It is worth noting that there are not so many enterprises engaged in this type of activity. Production is not widespread in Russia. Therefore, calculating profitability is very difficult.

Workshops that operate in several shifts and produce about 500 thousand units of product per month bring considerable profit to their owners. As experts’ calculations show, a beginner in this business can receive a monthly income equal to 500 thousand rubles. In this situation, the enterprise will fully pay off only after 3 years. However, the profit could be greater. After all, this indicator depends on how sales are organized finished products.

Paper cups are a convenient and environmentally friendly type of disposable containers and packaging. The raw material used is laminated paper with a density of 150-350 g/m², with one-sided or double-sided lamination, depending on the technological requirements. For example, for the manufacture of cups for hot drinks, it is allowed to use paper with a one-sided laminated coating. For cold drinks, cups with double-sided lamination are used. For hot drinks, it is also recommended to use two-layer paper glasses with a smooth or corrugated (corrugated) outer surface. Due to their low thermal conductivity, such glasses make it possible to avoid strong heating of the outer surface of the glass, as well as to maintain the temperature of the contents for a longer time.

The production of paper cups is a sequential process consisting of such stages as: printing on laminated paper in rolls or sheets, cutting blanks for the sidewalls of the cups (shells), forming the cups using appropriate equipment, and packaging the finished product. Printing is carried out using flexographic, offset methods, or using screen printing. The choice of equipment for the production of paper cups is determined by the type of product that is planned to be produced, the planned production volumes, the type of equipment already available, as well as the project budget and the possibility or economic feasibility of assigning certain technological stages in the production of disposable paper tableware for outsourcing.

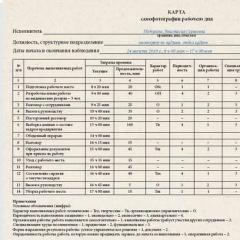

Paper cup production scheme

Making paper cups is promising production, which does not require large financial investments at the start and special knowledge. Disposable tableware is in stable demand, both in megacities and provincial cities. As the production of disposable paper cups gains momentum, plastic products are losing their relevance. This is due to the fact that paper is an environmentally friendly, harmless material that completely disintegrates within 3 years.

Our business assessment:

Starting investment – 1,000,000 rubles.

Market saturation is low.

The difficulty of starting a business is 7/10.

Project Features

The market for paper tableware in Russia is practically non-existent. There are about 20 small enterprises located in the central part of the country and in the Urals, whose field of activity is the production and sale of cups. More than half of the enterprises produce only paper cups for coffee. Foreign manufacturers offer customers large assortment cups of different shapes, sizes, colors. The main suppliers are European companies, as well as Korea, China, and Vietnam.

Opening a mini production of paper cups in Russia means organizing a promising enterprise, which over time will begin to bring benefits to its owner good profit. This is due to low competition, year-round demand for products and a wide range of consumers. You just need to study the relationship between supply and demand in the region where you are opening a mini-workshop and buy special equipment.

Advantages of a paper tableware business

Making paper cups as a business has a number of undeniable advantages:

- investments fully pay off in six months (sometimes 12 months);

- the amount of start-up capital required for the purchase of equipment and raw materials does not exceed 600,000 rubles;

- the production line can operate for 24 hours;

- powerful machines are capable of producing up to 50 cups per minute;

- the latest technologies used in manufacturing disposable tableware, guarantee high quality products.

Paper cups are made from special laminated cardboard, the edges of which are fixed using ultrasonic welding.

Stages of enterprise organization

To organize a business you need:

- register a company and choose a form of taxation;

- rent a room with an area of at least 50 m2;

- buy equipment for the production of paper cups;

- purchase raw materials;

- obtain permission from the SES, firefighters, and relevant local authorities;

- hire staff.

The qualifications of the employees do not matter because the production of paper cups is modern equipment– this is completely automated process, absolutely safe for humans and the environment.

A business plan for the production of paper cups is drawn up based on information obtained after studying the market in the region where the enterprise was opened. Market research will help you find the difference between supply and demand, determine the presence of competitors and fill an empty niche.

Experts say that the most popular are 100-gram coffee cups, which are often used in trade today. Tea glasses of 200 and 300 grams are no less popular. Dishes are used not only for hot drinks, but also for cold drinks.

Manufacturing technology

The process of producing disposable paper cups is very simple and does not require any skills. You need to take a sheet of special thick paper or cardboard, with or without a pre-printed design. This sheet is wrapped around a special shape, its edges are glued or welded. The bottom is inserted into the product removed from the blank.

Equipment selection

Paper Cup Production Line

The price of equipment for the production of paper cups depends on the model of the device and the country of manufacture. The main suppliers of equipment used in the manufacture of disposable tableware are the USA, European countries, China and Korea. European equipment is distinguished not only by its efficiency, productivity (up to 250 products per minute), power, but also by its high cost. The price of machines varies from 1,000,000 rubles. and higher.

Machines for producing paper cups are relatively inexpensive. The downside of the devices is not very high-quality assembly, which entails frequent breakdowns and repairs, and low productivity (from 30 to 80 glasses per minute). An entrepreneur choosing equipment must carefully read the documents supplied with the devices, and also pay attention to the manufacturer’s reputation in the market. This will help you choose and buy a high-quality machine that will last for a long time. The average cost of the machine is 600,000 rubles.

The machines differ in the way they are soldered. Ultrasonic method ensures reliable fixation and continuous operation at high speeds. Thermal soldering is considered more reliable and in a simple way gluing workpieces.

An entrepreneur needs to purchase replacement blanks to produce products of different dimensions, since the machines are designed to produce utensils of the same size. The production of paper cups with a logo, inscriptions and ornaments cannot be done without a machine that prints on paper. A paper cutting machine will speed up the process of cutting blanks from paper.

Consumables

Paper cups are made from thick laminated paper or cardboard. The material must have a high density: from 120 to 280 grams per m2. More recently, Finnish paper was the undisputed leader. Currently, the popularity of domestic manufacturers is growing.

An entrepreneur organizing production should know that the production of 400,000 glasses (per month) will require about 5 tons of raw materials.

Enterprise profitability

Since the production of paper cups is not yet widespread in Russia, it is quite difficult to make accurate calculations. Existing workshops, working in two shifts, producing more than 500,000 products monthly, bring their owners quite a large profit. According to experts, a beginner can count on an income of up to 500,000 rubles. per month. The investment will pay off within 2-3 years.

The amount of revenue directly depends on how well the sales of finished products are organized. The main buyers are hot food outlets, cafes, vending enterprises, restaurants fast food and others. Products can be sold to wholesale trading companies.

Over time, you can expand your business by taking up the production of paper plates and packaging. You can also offer customers advertising on cups.

The first step is to rent a space to install equipment and store products. Two zones will be required: the first - for the production of products, the second - for storing them. In the first room, a machine, a molding machine and other necessary equipment are installed.

The total area of the workshop must be at least 50 sq.m. The exact size depends on the parameters of the equipment - this is the factor that should be taken into account when renting. The premises must have electricity (380 volts), sewerage, hot and cold water supply (for the comfort of employees).

As for the required working personnel: the minimum number of people on staff is three employees: a driver, two workers per line. The qualifications of workers in this case are not important - the production of cups is fully automated and requires only control and timely supply of materials.

Paper cup production equipment

The main expense item for glasses is the purchase of equipment. The first thing you need to buy is a molding machine. They differ from each other by the method of welding the vertical seam of the glass.

Cheap models make seams by electrical heating and are distinguished by their simple design and comparative low cost. Since we are considering small business, then we’ll stop at them. With the help of such equipment, cups for coffee and other hot drinks are produced; they are suitable for carbonated drinks and ice cream.

The molding machine consumes about 5-7 kW, producing an average of 40 cups per minute. The minimum configuration of a production line should also include:

- press for making blanks;

- machine for making lids;

- a special printer for laminated paper (with its help you can apply a logo or inscription to a disposable cup).

Good equipment is produced by the Japanese company HORAUF(quite expensive), the JBZ series is popular. Since we are considering a small business, it makes sense to buy used equipment. The price for it is 1.5-2 times cheaper than for a new one.

Raw materials for the production of paper cups

For production, you will need materials: a cardboard sheet with a density of 120 to 80 g/sq.m., or thick laminated paper. The best paper and cardboard are produced by Finnish companies, but it is cheaper to purchase in Russia.

Regarding material consumption: to produce 100 thousand products you will need about 1 ton of raw materials.

Paper cup production technology

The production process is quite simple and is carried out in several stages. First, a drawing or inscription is applied to a sheet of paper or cardboard using a printer. After this, using special forms, the machine wraps the sheets into the desired shape and glues them together.

After removing the product from the mold, a pre-prepared round base is inserted. Thus, no difficulties arise in the production of glasses - the process is carried out very quickly.

Sales of products

There should be no problems with the sale of cups for hot and cold drinks: the high demand for them is due to the large number of takeaway coffee outlets and enterprises catering, cafe. They are the main consumers of the products.

Since the production volumes of glasses are quite large, for complete sales it is better to enter into an agreement with several buyers. You can advertise on the Internet or call suitable companies directly and send your price list.

Expenses and income

First, let's calculate how many units can be produced per month with uninterrupted line operation 5 days a week (eight-hour working day). As noted above, 40 cups are produced per minute, therefore, per day - 19,200 units, per month - 384,000. One unit of production costs about $0.05. Total income per month: approximately $19,200.

Initial Investment: used production line – $9 thousand, redecoration of the premises, business registration – $3000.

Monthly costs include: rental costs ($1000), employee salaries (3*300=$900), raw materials (almost 4 tons) - $450*4=$1800. Result: $3700. Net monthly profit will be approximately: $19,200 -$3,700 =$15,500.

The production of paper cups is an important advantage of which is the absence of high competition. If you sell your products correctly, you can get a good and stable income.

Some people are becoming interested in creating paper cups in order to use them for personal needs (to provide their large company with designer products) or to sell them. To successfully create a product, you will need equipment for the production of paper cups, as well as consumables.

Before purchasing equipment, you must carefully study all the details of your future business.

What may be required

To create a paper glass that will be used for coffee or other hot drinks, you need to purchase the following things:

- molding machine (including for lids);

- die cutting press;

- the premises in which the production workshop will be located;

- raw materials;

- printing machine

A large capital will be required to purchase all the required equipment. An important device, without which it is impossible to start production, is a molding machine; it is this that you will need to pay maximum attention to.

All devices available on the market differ in their capabilities. Cup making machines differ from each other in the following characteristics:

- speed of product creation;

- sizes of products received;

- type of raw materials used in the production process;

- own dimensions;

- power consumption.

High-speed machines capable of handling two-layer raw materials are preferred. Some entrepreneurs purchase technical equipment to create small glasses up to 100 ml, others to create large glasses from 150 to 300 ml. Before purchasing, you need to decide what the final product should be in order to select the appropriate equipment.

Raw material base

Raw materials are an integral part of any production; they are purchased after purchasing all the equipment. The purchase is made based on the characteristics of the forming machine. The raw material is laminated single-sided or double-sided paper with a dense structure.

An interesting property of a paper glass is that it has low thermal conductivity. It does not allow the drink to cool down and does not burn a person’s hands. Therefore, a paper container is best for hot drinks.

The raw materials are cheap for the manufacturer, so it is possible to make a good profit by producing paper drink containers.

You will need to find a reliable supplier in order to receive raw materials at a favorable price and within the required time frame. If planned big business, then you need to find several suppliers at once. Raw materials are produced in several countries; the most popular consumables are from companies:

- Finnish;

- Russian;

- Chinese.

Finnish paper is considered the best; the domestic manufacturer provides fairly high-quality consumables.

What investments does it require?

It is worth noting that purchasing equipment and starting production requires large cash investments. Even one machine for creating paper products will cost a person a tidy sum. The minimum starting set of technical equipment will require at least 60 thousand dollars.

Additionally, you will need to pay personal attention to the business, as well as search for workers, partners, and places to sell goods. All this requires preparation; it is advisable to already have it before purchasing ready business plan, which will contain a strategy from the beginning to the launch of the project.

Working with the devices requires special skills, so you will need to hire qualified workers. If you purchase a functional molding machine, it is easy to start the process in semi-automatic and even automatic mode.

The quality of the resulting coffee containers depends entirely on the functionality of the technical equipment and the skills of the worker. At an early stage, many actions can be carried out independently; if there is a profit, then over time the entrepreneur will be able to automate all processes by hiring workers.

Where to buy equipment

Many organizations are engaged in the sale of devices for the production of paper products. IN large companies A wide range of devices is offered. To start production, simple options are suitable technical devices. If the budget is unlimited, it is advisable to purchase multifunctional equipment.

Machines for creating paper products can be partially or fully automated. Maintenance consists of monitoring the process and placing raw materials in special compartments of the devices.

Equipment for the production of coffee cups must have all certificates. An important point is the provision of a guarantee. The equipment has a high cost, so the buyer must be confident in the equipment purchased.

Some companies immediately offer a set of all the necessary devices for creating paper products. It is worth noting that the set will be cheaper than purchasing all the equipment separately.

The search for an organization is carried out via the Internet; all modern companies have their own website and even an online store, so it will be possible to compare several products with each other.

Types of paper cup production equipment

If you have doubts about choosing a particular product, then you need to use the help of a specialist to get advice. This could be a person from a company that sells the product or an independent expert who, for a certain amount, will help you choose high-quality equipment.

What is required to operate the equipment

If a person has acquired everything required to successfully create coffee containers, then it is easy to begin production. Active work starts if the following conditions are met:

- There is staff (only 1 person is enough to operate a small machine).

- The room has been prepared.

- There is an uninterruptible power supply (almost all equipment can operate around the clock, the service life of modern products is very high).

- A sales point for future products has been found (the machine is capable of producing from 5 to 20 thousand glasses of a given shape and volume per day).

- There is a reliable supplier of consumables.

An entrepreneur must officially register his activities and be prepared to pay taxes to the state on a monthly basis. The equipment will be checked by experts. If it meets safety requirements, permission will be given to start production.

During operation, the process should be monitored; the equipment requires supervision; if used incorrectly, a breakdown can easily occur that does not fall under the warranty category.

Car repairs are often expensive, so you need to pay close attention to the work.

All devices must be checked for defects. Use is carried out in accordance with the instructions, which are necessarily included in the kit.

Sales of goods

After successful production of the product, the moment of sale comes. A huge number of cups are produced within one day, so sales are carried out exclusively in bulk. Can be found regular customers, usually various fast food chains and cafes are interested in the product.

An entrepreneur can agree with a coffee establishment that he will supply a huge number of paper cups. It is worth noting that you will need to find several clients to get the necessary profit.

You should not expand production until a sufficient number of places to sell the goods are found.

At the initial stage, you will need to somewhat limit the possibilities.

Is it worth purchasing equipment?

Typically, equipment pays for itself in about 11–24 months if a person does everything correctly. Everyone decides for themselves whether it is worth starting to create paper products. The profitability of the business is high, and it does not require specialized skills for success.

The low barrier to entry in terms of skills is the main advantage of starting this entrepreneurial activity.

Equipment and raw materials will require a large investment of money. High demands capital is keeping many people away from their dream of making coffee cups.

If a person wants to start his own business and has a large amount of money, then he can opt for the production of glasses. This matter should be shared with a partner, in this way simplifying the purchase of expensive equipment.

If unsuccessful, you can easily sell the equipment at almost the same price at which it was purchased. The business of selling coffee glasses is growing rapidly and provides invaluable experience to every person.