Logistics: essence, tasks, functions. Logistics – what is it in simple words? Who are logisticians? Logistics as a practical activity

Logistics - activities that optimize all processes of production, distribution, transportation and sales.

Logistics is a scientific and practical direction of management, which consists in the effective management of material and related information and financial flows in the spheres of production and circulation.

Logistics is the theory and practice of managing material and related information flows.

Logistics is an interdisciplinary scientific field directly related to the search for new opportunities to increase the efficiency of material flows.

Logistics is the science of planning, control and management of transportation, warehousing and other tangible and intangible operations performed in the process of bringing raw materials and materials to manufacturing enterprise, in-plant processing of raw materials, materials and semi-finished products, finishing finished products to the consumer in accordance with the interests and requirements of the latter, as well as the transfer, storage and processing of relevant information.

Logistics is the activity of managing the movement and storage of raw materials, components and finished products in economic circulation from the moment the supplier receives money until the moment the money is received for delivery of the finished product.

Logistics is end-to-end planning, organization and control of all types of movement and warehousing activities that ensure the passage of material and associated information flows, from points of purchase of raw materials and components to points of final consumption.

Logistics is a general point of view: strategic, tactical, operational for the company, as well as its business partners, with material flow as an integrator.

Logistics is the science of the relationships and interactions of supply, production, sales and transport.

Logistics is a theoretical justification and practical activity for planning, management and control of material and relevant information flows entering an enterprise, processed there and leaving this enterprise.

Logistics is a direction in the economic sphere, within which the problem of developing and implementing an integrated system for managing material and information flows in production, transport, and distribution is solved to fully satisfy demand.

Logistics is the science of managing and optimizing material flows, service flows and related information and financial flows in a certain micro- and macroeconomic system, to achieve its goals.

Logistics is an integral management tool that contributes to the achievement of strategic, tactical or operational goals of a business organization through effective (from the point of view of minimizing total costs and meeting the requirements of end consumers for the quality of goods and services) management of material and (or) service flows, as well as related ones flows of information and financial resources.

Logistics is a system developed for each enterprise with the aim of optimally, from the point of view of making a profit, accelerating the movement of material resources and goods inside and outside the enterprise, starting from the purchase of raw materials and supplies, passing them through production and ending with deliveries finished products consumers, including the information system connecting these tasks.

Logistics - ways to organize the activities of an enterprise, allowing you to combine efforts various units producing goods and services in order to optimize financial, material and labor resources used by the company to achieve its economic goals.

Logistics is the art and science of management, technology and technical methods, which provide for the planning, supply and use of means of transportation in the implementation of planned operations to achieve the goal.

Logistics is a broad range of activities concerned with the efficient movement of final products from the end of the production line to the customer, including the movement of raw materials from the source of supply to the beginning of the production line. These activities include transportation, warehousing, materials handling, protective packaging, inventory control, manufacturing and warehouse location selection, product orders, demand forecasting, marketing, and customer service.

Logistician is the organizer of the implementation of processes, including management processes, in the most appropriate way - taking into account scientific and economic justification and calculations, common sense, logic and consumer interests.

The main six conditions, for the maximum fulfillment of which, any organization is looking for a special person called a “logistics specialist” and entrusting the fate of the business into his hands:

- required item

- at the right time,

- in the right place

- in the required quantity,

- with appropriate quality and service,

- at the lowest cost.

Upon closer acquaintance with the concept of “logistics”, it turns out that this “young” science is nothing at all - about two thousand years old. And the special employees of the Roman Empire who were responsible for the distribution of food were called, of course, logistics. It can be assumed that one of the reasons for constraining the application of logistics principles in the economy was the underdevelopment of transport infrastructure and information technology. And since all this began to take shape and develop rapidly in the second half of the twentieth century, the development of the use of logistics in the economy occurred during this period. Although, of course, we must not forget that the basic principles of logistics were formed precisely where the requirements for the organization of material and information flows are much higher than in civilian life - in military affairs. Moreover, long before the use of logistics in economic systems. Some principles of logistics were used in Napoleon's army, but as an integral military discipline, logistics was formed only by the middle of the 19th century. During the Second World War, logistics was actively used in the material and technical supply of the US Army and allies.

Logistics has been known for two thousand years. In The Roman Empire there were employees named logisticians. These people took part in supplying of food to the population. At the end of the 19th century and during The First and The Second World Wars supplying of the army with equipment and food was named logistics. Every military man knew that if you wanted to win a battle you could not do without good supply. In 50th rules of logistics began to be used in business. It was necessary to reduce costs. Since 50th logistics has been actively developing. Nowadays logistics is an important part and instrument of business it controls flows of goods and information. The result of using logistics is acceleration of the turnover and reduction of costs.

Six rules of logistics: “Getting the right product, to the right place, at the right time, in the right quantity, with the right quality, for the right cost.”

In view of the fact that there are as many definitions of logistics as there are logisticians, I wanted to collect in one place all, or almost all, the main definitions of logistics, so that you can become familiar with them and finally understand the need and inevitability of using logistics to achieve maximum efficiency of any activity, both public and private. Or maybe someone would like to come up with and add another new definition of logistics here?

HISTORICAL AND PHILOSOPHICAL DEFINITIONS OF LOGISTICS

Logistics - organizing the supply of the army and managing its movements.

Logistics - scientific and practical activities that optimize transportation processes.

Logistics is a smart organization.

Logistics - mathematical logic.

Logistics - planning a clear sequence of actions.

Logistics is the art of reasoning and making calculations.

Logistics is the art and science of identifying needs, as well as acquiring, distributing and maintaining them throughout life. life cycle that provides these needs.

SOME IMPORTANT CONCEPTS AND PRINCIPLES OF LOGISTICS (thesis)

The objectives of logistics are to reduce the time it takes for goods to pass through distribution channels and minimize costs along the entire route of goods flows with the maximum level of service for intermediaries and end consumers.

Main types of logistics systems:

Pull logistics systems - goods are shipped by suppliers as they are received and based on current orders from wholesale and retail sales links. Sales strategy - stimulating demand for goods in the retail trade.

Push logistics systems - goods are shipped by suppliers to wholesale and retail chains according to a pre-agreed strict schedule based on preliminary long-term orders of wholesale and retail chains, adjusted by suppliers. Sales strategy - preliminary, ahead of demand, formation of inventories in wholesale and retail sales links.

Just-in-time systems - goods are shipped according to a pre-agreed schedule, assortment and quantity of each item. Sales strategy - retail trade without safety stocks.

Combined systems.

The effectiveness of logistics depends on the quality of organization, management, mechanization, computerization, and personnel training.

The novelty of the logistics approach is organic mutual communication, integration of transport management, warehousing, inventory, personnel, formation of information systems, commercial activities etc. The goal of logistics is end-to-end management of material flows.

The fundamental difference between the logistics approach to managing material flows and the traditional one is the identification of a single function for managing previously disparate material flows; in the technical, technological, economic and methodological integration of individual links of the material-conducting chain in unified system, providing effective management through material flows.

Main tasks of logistics:

- inventory planning based on demand forecast;

- determination of the required production and transport capacity;

- development of rational scientific and practical principles for the distribution of finished products based on optimal control material flows;

- development of rational principles for managing transshipment processes and transport and warehouse operations in the chain supplier - production - distributor - consumer;

- construction of various variants of mathematical models of functioning logistics systems;

- development of methods for joint planning of supply, production, warehousing, sales, shipment and transportation of finished products.

The logistics method examines and optimizes the emergence, transformation or absorption of material and related flows at a certain economic object that functions as a system, that is, realizing the goals set for it and considered in this sense as a single whole.

An important aspect of logistics is the mutual influence of logistics and company strategy on the creation of new competitive advantages in the market, i.e. on the final goals.

Main functional areas of logistics:

- purchasing,

- production,

- distribution,

- transport,

- informational,

- resource (personnel).

Macrologistics - solves issues related to market analysis of suppliers and consumers, development of a general distribution concept, placement of warehouses at the service area, choice of mode of transport and vehicles, organization transport process, rational directions of material flows, with the choice of a transit or warehouse scheme for the delivery of goods. The main task is to develop a balanced and justified comprehensive proposal that would contribute to achieving the highest efficiency of the company, increasing its market share and gaining advantages over competitors.

Micrologistics - solves local issues within individual firms and enterprises.

Savenkova T.I. Logistics

CONTENT

1.1. Development of logistics as a science and its practical implementation

1.2. Logistics in economics

1.3. Logistics. Macro and micro logistics

1.4. Material flow and its meters

1.5. Classification of material flows

1.6. Volume forecasting methods material flow

1.7. Functional areas of logistics

1.8. Logistics functions

1.9. Logistics systems

1.10. Supply chain and logistics costs

1.11. Organization of logistics at the enterprise

1.12. Interaction of logistics with other organizational processes.

Topic 2. Basics of transport logistics

(Issues covered)

2.1. The essence and objectives of transport logistics

2.2. Transport logistics and distribution

2.3. Intra-production transportation

2.4. Logistics approach to organizing the transport process

2.5. Selecting a vehicle

2.6. Types of transportation

2.7. Selecting a transportation route

2.8. Determination of logistics costs in transport. Transport tariffs

2.9. Tariff for transportation of cargo in containers

2.10. Stevedoring work in linear maritime traffic

2.11. Transport operations included in the freight charge

2.12. Logistics concept for building a transport service model

Topic 3. Production logistics

3.1. Subject of production logistics

3.2. Characteristics of production logistics

3.3. Push and pull systems

3.4. Enterprise logistics system management

3.5. Flexible production and logistics systems

3.6. Qualitative and quantitative flexibility

3.7. Prospects for the development of the production and logistics system

Topic 4. Information logistics

(Issues covered)

4.1. Information logistics flow

4.2. Information flow during cargo transportation

4.3. Information logistics systems

4.4. Classification of information systems

4.5. Construction of information systems in logistics

4.6. Control information system With feedback

4.7. Information tasks in logistics

4.8. Information Technology in logistics

Topic 5. Purchasing logistics

5.1. Goal and objectives procurement logistics

5.2. Studying commodity market

5.3. Search for suppliers

5.4. Criteria for optimal supplier selection

5.5. Procurement

5.6. Legal basis procurement

5.7. Supply Management

5.8. Order fulfillment control

Topic 6. Inventories

(Issues covered)

6.1. Classification inventories

6.2. Inventory management

6.3. Optimal inventory size

6.4. Inventory control

6.5. Inventory management systems

6.6. System with fixed order size and time period between orders

6.7. Inventory structuring

6.8. Determining the optimal order size

6.9. Inventory rationing methods

Topic 7. Warehousing logistics

7.1. Functions and tasks of warehousing in the logistics system

7.2. Operations performed in the warehouse

7.3. Types, functions and classification of warehouses. Logistics process in a warehouse

7.4. Characteristics and classification of warehouses industrial enterprises

7.5. Peculiarities warehouse operations in wholesale warehouses

7.6. Selecting a warehouse

7.7. Efficiency of warehouse operations

7.8. The choice between organizing your own warehouse and using hired services

7.9. Methods for determining the location of a warehouse. Determining the optimal number of warehouses in the service area

7.10. Main parameters of warehouse zones

7.11. Calculation of the length of the loading and unloading front and determination of the warehouse area

7.12. Squares office premises and auxiliary warehouse area

7.13. Calculation of the required amount of storage equipment and warehouse capacity

7.14. Determining the required number of mechanisms for carrying out handling and transport operations

7.15. Warehouse performance criteria

7.16. Pricing policy in a warehouse complex

Topic 8. Distribution logistics

(Issues covered)

8.1. The essence of distribution logistics

8.2. Distribution logistics tasks

8.3. Functions of supplier distribution logistics and buyer purchasing logistics

8.4. Logistics channels and distribution chains

8.5. Product distribution channels

8.6. Distribution channel structure

8.7. Construction of a distribution system

8.8. The relationship between logistics and marketing

Topic 9. Logistics centers

9.1. Logistics center concept

9.2. Shopping areas

9.3. Logistics systems in wholesale trade

9.4. Logistics systems in retail trade

9.5. Integrated processes in trade

Topic 10. Logistics service

(Issues covered)

10.1. Application of the service in logistics

10.2. Logistics service levels

10.3. Determining the optimal volume of logistics services

10.4. Creation of a logistics service and optimization of its volume

Topic 11. Logistics cost management

11.1. Cost classification

11.2. Logistics costs

11.3. Order processing costs

11.4. Inventory costs

11.5. Supply costs

11.6. Transportation costs

11.7. Warehousing costs

Glossary of terms

HIGH SCHOOL LIBRARY

T.I. Savenkova

LOGISTICS

Tutorial

Recommended by UMO for education in finance, accounting and global economics as teaching aid for students,

students in the specialties “Finance and Credit”, “Accounting, Analysis and Audit”

5th edition, stereotypical

publishing house OMEGA-L

Moscow, 2010

UDC 658.51(075.8)

BBK 65.291.592ya73-1

C12

Savenkova, Tatyana Ivanovna.

C12 Logistics: textbook. a manual for students studying in the specialties “Finance and Credit”, “Accounting, Analysis and Audit” / T. I. Savenkova. - 5th ed., erased. - M.: Omega-L Publishing House, 2010. - 255 pp.: ill., table. - (Higher School Library). ISBN 978-5-370-01793-3 Agency CIP RSL

The tutorial covers the basics logistics activities by main functional areas: logistics approaches and management methods in the field of transport, inventories, production, warehousing, pricing, etc. For better assimilation of the material, the publication includes questions and assignments, tests, and a dictionary of terms.

Intended for students studying economics.

UDC 658.51(075.8)

BBK 65.291.592ya73-1

ISBN 978-5-370-01793-3

© Savenkova T.I., 2006

© Design. Publishing House LLC

"Omega-L", 2010

Topic 1. General characteristics logistics and factors of its development

“The proposed material of the textbook is divided into 11 topics and is devoted to logistics - the science of managing flow processes in market economy. The sequence of presentation of the material allows you to get an idea of the main functional

areas of logistics, logistics methods of “consolidated” management of material flows.

In planning logistics systems, the main thing is the creation of new business opportunities that provide the possibility of an organization/enterprise taking into account the constant search for an optimal development strategy based on special mechanisms for its implementation.

Logistics objects - material, financial, information flows and service flows along the path of movement from the primary

source to the final consumer. The main objectives of the discipline: studying conceptual apparatus; mastering the principles and methods of logistics knowledge of organizations/enterprises as complex artificial systems; consideration of possibilities

application of the theory and methodology of logistics in enterprises, etc.

Logistics as a discipline in the system of training economists and managers is associated with the following disciplines: philosophy,

economic theory, management, organization theory, development management decisions, enterprise economics, marketing, statistics, computer science, etc.”

Development of logistics as a science and its practical implementation.

Logistics (from the Greek word logistike) is the art of calculating and reasoning. The history of the emergence and development of logistics is a thing of the past. In the Roman Empire, there were servants who bore the title of “logistics” or “logistics”, who were involved in the distribution of food products.

There is an opinion that logistics has grown into a science thanks to military affairs, which includes such a wide range of issues as planning, management and supply, determining the location of troops, as well as the construction of bridges, roads, etc. Over time, under the influence various factors, logistics began to move from the military field to the sphere of economic practice, taking shape as a theory of management of commodity and material resources in the sphere of circulation, and then production.

Logistics interaction technology was developed various types transport (within the transport hub), which formed the basis for the development of a unified European transport system of the countries of the European Union.

Logistics in economics

In economics, logistics refers to scientific and practical activities related to the organization, management and optimization of the movement of material (raw materials, goods, semi-finished products) and accompanying (information and financial) flows from the source of raw materials to the final consumer (Fig. 1.1).

To control the movement of a material flow, you need to know how to influence this flow:

choice of vehicle;

selection of the optimal transportation route;

determining the optimal level of inventory in warehouses; selection of the number and territorial location of warehouses

And wholesale bases;

determining the optimal packaging size of the finished product

products, etc.

The main goal of optimal control of the movement of material flow is to increase competitiveness through:

reducing costs for cargo promotion;

optimization of inventories along the entire route;

reducing the time it takes for goods to pass from the primary source to the consumer;

improving the quality of customer service.

The use of logistics is explained by a number of reasons, among which three can be distinguished.

1. Reaching the limit of production efficiency has necessitated the search for unconventional ways to create competitive

benefits. Entrepreneurs began to pay attention not only to the product itself, but also to the quality of its delivery. Cash, invested in the distribution sphere, began to influence the position of the supplier in the market. In logistically organized material supply chains, the cost of goods delivered to the final consumer turned out to be lower than the cost of the same goods passed along the traditional route.

2. The increase in energy costs forced us to look for methods to increase the efficiency of transportation; coordinated actions of all participants in the logistics process were required.

3. The application and development of logistics became possible thanks to the implementation computer technology, which made it possible to manage material flows at all stages of movement.

IN modern economy There are three stages in improving logistics as an economic discipline.

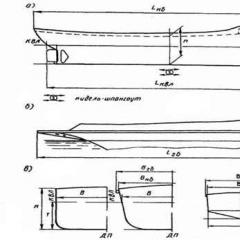

At the first stage of logistics development(Fig. 1.2) transport, transshipment terminal, warehouse began to work according to a single schedule, a single technology, for the final economic result.

The container in which the cargo is shipped is selected taking into account the transport, and the characteristics of the transported cargo determine the choice of transport

etc.

The second stage in the development of logistics characterized by distribution and production process(Fig. 1.3). From the point of view of logistics development, it is characterized by:

centralization of physical distribution;

long-term planning in the field of logistics;

reduction of reserves in material supply chains;

determining distribution costs;

implementing measures to reduce the cost of promoting goods.

The use of logistics in production has made it possible to reduce inventories, improve the quality of service due to timely execution of orders, improve the use of equipment, etc.

Third stage characterized by complete integration of all elements of the logistics material flow (Fig. 1.4). An example of such integration is the development of transport and technological systems. This is due to the emergence of specialized vessels: container ships, timber carriers, package carriers, specialized transshipment complexes, warehouse equipment, etc. An important factor, which made it possible to combine all stages of the material flow from raw materials to finished products and beyond, was the development of communication technologies based on global computer networks, which in turn contributed to the development of industries engaged in the provision of logistics services.

Related information.

To maintain high competitiveness of an enterprise, the logistics chain must constantly develop and improve. To do this, you need to have a way to determine the following points:

how well the supply chain currently performs;

in what direction it should be improved;

How successful is the process of transformation of the supply chain in the chosen direction?

Answers to these questions can be obtained by analyzing the indicators of logistics activities, because they reflect in a concise form the state of logistics functioning. Indicators can be direct or indirect, absolute or relative. Indirect indicators are often related to finance, such as profitability or payback period. On the one hand, financial indicators:

easily identified;

look convincing;

allow for comparison of the results obtained;

give big picture current state logistics system;

are popular.

But at the same time they have a number of significant disadvantages:

they reflect past performance;

respond slowly to changes;

depend on a number of accounting techniques;

do not take into account important aspects of logistics;

do not show specific problems and ways to solve them.

Direct indicators are more suitable for analyzing the causes of the current situation and finding management solutions. These include: the weight of delivered goods, the speed of inventory turnover, the distance of cargo transportation, the number of unfulfilled orders, the number of violations of delivery conditions, etc.

Absolute indicators include single (for example, sales volume or availability) and total (balance sheet indicators, income and expense figures). Relative indicators are divided into specific (ratios of parameter values to the total number of any objects), interrelated (ratios of different quantities with each other), indices (ratios of homogeneous quantities with each other, the denominator is the base quantity).

To the most general indicators supply chain activities include indicators characterizing supply chain capacity and productivity.

LC power is not a given constant value, as it might seem at first glance, but actually shows the efficiency of organizing the use of resources. The fact is that power, firstly, depends on the way resources are used, and secondly, it changes over time. For example, the professionalism or unprofessionalism of managers can respectively increase or decrease the throughput of an enterprise with the same available resources. In addition, during the workday, employee productivity decreases, which leads to a decrease in power. In this regard, as mentioned earlier, design, effective and actual power are distinguished.

Besides absolute value capacity, to analyze the efficiency of logistics activities, the capacity utilization factor is used, showing the share of the design capacity actually used. For example, if a fleet of vehicles is designed to deliver 100 tons of materials per week, but actually only delivers 60 tons, then its capacity utilization rate is 60%.

Performance– one of the most widely used indicators. There are several types of performance:

Overall Performance– the ratio of the total throughput to the total amount of resources used.

Logistics costs (costs)– the sum of all costs associated with the implementation of logistics operations, as well as costs for personnel, equipment, premises, warehouse stocks, for the transfer of data on orders, stocks, deliveries.

Direct costs can be directly attributed to a product, service, order, or other specific medium. Indirect costs can be directly attributed to the carrier only by performing auxiliary calculations.

Regulated costs- costs that can be controlled at the division level. Unregulated costs are costs that cannot be influenced at the division level, since these costs are regulated at the level of the company as a whole or in an external link in the supply chain (at another enterprise).

Productive costs- costs of work aimed at creating added value that the consumer wants to have and for which he is willing to pay. The costs of maintaining logistics activities do not in themselves create value, but they are necessary, for example, transportation costs, placing orders, checking the work of employees, maintaining product records. Control costs are the costs of activities aimed at preventing undesirable results of customer service.

1. 1. Development of logistics as a science and its practical implementation.

Logistics (from the Greek word logistike) is the art of calculating and reasoning. The history of the emergence and development of logistics is a thing of the past. In the Roman Empire, there were servants who bore the title of “logistics” or “logistics”, who were involved in the distribution of food products.

There is an opinion that logistics has grown into a science thanks to military affairs, which includes such a wide range of issues as planning, management and supply, determining the location of troops, as well as the construction of bridges, roads, etc. Over time, under the influence of various factors, logistics began to move from the military field to the sphere of economic practice, taking shape as a theory of managing commodity and material resources in the sphere of circulation, and then production.

A logistics technology for the interaction of various modes of transport (within a transport hub) was developed, which formed the basis for the development of a unified European transport system for the countries of the European Union.

From the book Real Estate Investments author Kiyosaki Robert TohruPractical Feasibility Your project must above all be realistic, practical and common sense. How is the feasibility of a project determined? Any lender should look at it and say, “I think this idea should work.” Prospects

author3.3. Paradigms of logistics A paradigm is a methodology, methods and ways of solving problems that have prevailed for a certain period of time in society. Logistics paradigms are closely related to the four stages of logistics evolutionary development. The following paradigms are distinguished

From the book Basics of Logistics author Levkin Grigory Grigorievich3.4. Principles of logistics Principle is the basic, initial position of a theory, doctrine or science. The principles of logistics are generalized data, laws of phenomena taken from expert observations. There are general conceptual, system-wide and specific principles of logistics.

From the book Basics of Logistics author Levkin Grigory Grigorievich4.1. Logistics methods Improving the operation of logistics systems is impossible without collecting reliable information and its subsequent analysis. Therefore, in the general theory and practice of logistics, increased attention is paid to logistics research, including methods

From the book Principles of Economic Science author Marshall AlfredAppendix B. Development of economic science. § 1. We have seen that economic freedom has its roots in the past, but basically it is a product of very recent times; now we will trace the parallel development of economic science. Social conditions,

authorQuestion 63 Contribution of Nobel Prize laureates of the 21st century. in economics in the development of microeconomics

From the book Economic Theory author Vechkanova Galina RostislavovnaQuestion 105 Development of macroeconomic science in the works of Nobel Prize laureates of the 21st century. By

From the book Opening a Car Repair Shop: Practical guide authorPractical activities

From the book Opening a Tire Repair: A Practical Guide author Volgin Vladislav VasilievichPractical activities

From the book Logistics author Savenkova Tatyana Ivanovna1. 8. Logistics functions Among the logistics functions at the level of business organization, experts distinguish basic, key and supporting functions. To the basic logistics functions include: supply, production and sales. These three functions are carried out practically

From the book Logistics author Savenkova Tatyana IvanovnaTopic 2. Fundamentals of transport logistics. 2. 1. The essence and objectives of transport logistics A significant part of logistics operations along the route of material flow is carried out using various vehicles. Transport is the connecting link between elements

From the book Logistics: lecture notes author Shepeleva Anzhelika Yurievna1.1. Logistics concept

From the book Management Practice human resources author Armstrong MichaelPRACTICAL IMPLEMENTATION 11. Prepare summary material.12. Make sure everyone is aware of the e-learning opportunity, the role they and their managers play in it, and the support they will receive from their trainers and facilitators.13.

From the book HR in the fight for competitive advantage by Brockbank WayneThe value proposition in defining line managers (development of organizational capabilities) and employees (development of individual capabilities) HR creates additional value for line managers. An HR leader can help managers get rid of

From the book Visualize It! How to use graphics, stickers, and mind maps to teamwork by Sibbet David7. Practical information Stickers and voting with dot stickers You have already become familiar with different ways of working with stickers on a large sheet of paper. Now let's look in more detail at the techniques that will help you achieve maximum benefit from using these

From the book Achieving Goals: A Step-by-Step System author Atkinson MarilynPractical work and developing effective actions? Considering our work today and your short and long term goals, what actions are you willing to take this week? What will you do this week to get closer to your achievement?